Over seven kilometers long, the San Francisco-Oakland Bay Bridge was constructed with around 250 million kilograms of steel and accommodates over a quarter of a million vehicles per day. If each vehicle is assumed to have a mass of 1800 kg, then the Bay Bridge must support a mass of 450 million kg of vehicles per day.

For those of us who have crossed a major bridge such as the Bay Bridge, the possibility of bridge failure is frightening. In 1989, the Bay Bridge failed: during the Loma Prieta earthquake, the vibrations from the earthquake sheared the bolts that fastened a section of the bridge into its seating. As the earthquake vibrations increased, the section was pushed to the east, and the west end of the section shifted beyond the edge of the seating, causing the entire bridge section to collapse; the collapse location was at pier E9, which is located halfway between Yerba Buena Island and Oakland.

The Bay Bridge was designed to withstand earthquakes by being flexible — but, apparently, not flexible enough. In fact, all bridges are designed to be somewhat flexible with an underlying and embedded “bend or break” design philosophy: it is assumed that the bridge will be subject to somewhat unpredictable external forces and torques caused by wind, temperature changes, heavy traffic loads, and sometimes even earthquakes. So if flexibility is crucial, how is it achieved?

BRIDGE ELASTOMERIC BEARING PADS

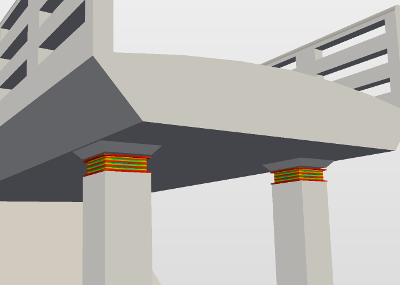

Bridge flexibility is achieved by, among other things, a component called a bridge elastomeric bearing pad. Elastomeric bearing pads are typically made of a strong and pliable material (e.g., neoprene). These pads are placed in between superstructures such as the bridge beam and substructures such as the vertical supports called piers. Their function is to transmit and distribute superstructure loads to the substructure and permit the superstructure to undergo necessary movements (compression, shear, and rotation) without developing any harmful overstress that might compromise the structural integrity of the bridge. In an extreme case, when the structural integrity of the bridge is compromised, the bridge could collapse.

Preventing collapse is not the only function of elastomeric bearing pads. The pads extend the life of bridges by reducing wear and tear on bridge materials — much like shoes allow human beings to walk longer distances; hence, the pads help governments save money by delaying the replacement of bridges.

Incidentally, at pier E9, which was the location of the Bay Bridge failure, elastomeric bearing pads were installed as part of a 1999 seismic retrofit project.

3D ENGINEERING SIMULATION IN BRIDGE DESIGN

Because bridge elastomeric pads are crucial to safe and cost-effective bridge design, elastomeric bearing pads are extensively prototyped and tested before they are used in production. Using simulation software as part of the process, it is possible to simulate an elastomeric bearing pad under different design and load assumptions and then observe its behavior. For example, the bearing pad can be assumed to be composed of an elastomeric material reinforced by steel plates, and three basic load cases can be simulated and observed: 1) compression, 2) compression with shearing, and 3) compression with rotation.

The results can be analyzed by observing Cauchy stresses in a contour plot. One can even observe that with the introduction of steel plates for reinforcement, the load carrying capacity of the bearing is enhanced.

CONCLUSION

As we have seen, elastomeric bearing pads play a crucial role in bridge safety, dependability, and longevity. Undoubtedly, simulation software is an important asset in this role.